More Projects

Sutter Roseville “Cart Wash and Ultra Sonic Cleaner” CSPD

December 16, 2021

UC Berkeley Bakar Bioenginuity HUB Laboratory Vacuum System

October 19, 2021

Stanford D&T Mechanical Room Control Air Compressor System Upgrade

September 8, 2021

UCSF 23A Dekker Medical-Laboratory Vacuum System

January 27, 2021

Stanford Valley Care Medical Air Dryer Upgrade Project

December 1, 2020

Stanford University School of Medicine Fairchild Laboratory Vacuum System Installation

Industry: Laboratories

Type: Equipment, Construction

Description

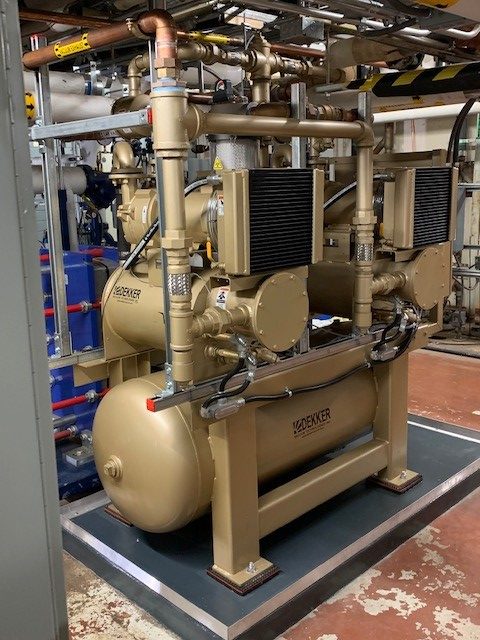

Installation of a (N) Dekker Laboratory Vacuum System with Solber HV Series Inlet Filtration.

Scope of Work

- Provide (N) AES-Dekker Laboratory Vacuum System

-

- AES-Dekker Laboratory Vacuum System Model AES-VMX0083MA2-00-DS

- (2) Dekker Titan single stage 5.5HP liquid ring vacuum pump skids.

- Capacity each vacuum pump 21.92 SCFM @ 21”HGVAC *Note the liquid ring technology may have a slight variance in CFM due to close tolerances between the vacuum pump impeller and vacuum pump body.

- Oil is Not used as a lubricant

- System Components Include:

- (2) TEFC Electric motors, 230/460 Volt, 3 Phase, Premium Efficiency.

- (2) Patented DX5 Discharge Separator-Reservoirs with 5 Stage Air/Oil Separation, Including Coalescing Filter.

- (2) Seal Fluid Isolation Valves

- (2) Y-Strainers

- (2) Seal Fluid Line Check Valves

- (2) Separator Drain Valves

- (2) Separator Sight Level Gauges

- (2) Temperature RTD for Discharge Temperature Indication and High Temperature Protection.

- (2) High/Low Oil Level Switches

- (2) Air-Cooled, Heat Exchanger Packages with Main Motor Driven Fan and Fan Guard.

- (2) Inlet Check Valves

- Inlet Manifold Including:

- (2) Inlet Isolation Valves

- (2) Inlet Flex Connectors

- Manifold Piping

- Discharge Manifold Including:

- (2) Individual Pump Drip Legs

- (2) Discharge Check Valves

- (2) Discharge Flex Connectors

- Manifold Piping

- (2) Sets of Hydraulic Hose Seal Fluid Line.

- (2) Inlet Filters

- (2) Vacuum Relief Valves

- Vacuum Receiver

- (1) Horizontal Grasshopper Tank Vacuum Receiver 120 Gallon

- (1) Receiver Sight Level Gauge

- (1) Receiver Drain Valve

- Electrical:

- (1) Duplex ControlDEK Control Panel

- Monitors, measures, and displays performance

- Identifies maintenance and fault conditions, prevents downtime, and preserves system quality.

- Standard 460V, 3 Phase, 60Hz (NEMA12, CUL Listed

- Custom PLC with 4.3” Color Touchscreen LCD with integral hour meter

- Across-line Magnetic Vacuum Pump Starter with 3 Phase Overload Protection

- RTD for discharge temperature indication and high temperature protection

- Vacuum On/Off capability with adjustable set points

- Vacuum transducer, for vacuum level indication

- Pressure transducer, for back pressure indication

- 24V Power Supply

- (1) Duplex ControlDEK Control Panel

- Solberg HV Series Filter UL850/1-200C (Shipped Loose for Field Installation)

- AES-Dekker Laboratory Vacuum System Model AES-VMX0083MA2-00-DS

Description

Installation of a (N) Dekker Laboratory Vacuum System with Solber HV Series Inlet Filtration.

Scope of Work

- Provide (N) AES-Dekker Laboratory Vacuum System

-

- AES-Dekker Laboratory Vacuum System Model AES-VMX0083MA2-00-DS

- (2) Dekker Titan single stage 5.5HP liquid ring vacuum pump skids.

- Capacity each vacuum pump 21.92 SCFM @ 21”HGVAC *Note the liquid ring technology may have a slight variance in CFM due to close tolerances between the vacuum pump impeller and vacuum pump body.

- Oil is Not used as a lubricant

- System Components Include:

- (2) TEFC Electric motors, 230/460 Volt, 3 Phase, Premium Efficiency.

- (2) Patented DX5 Discharge Separator-Reservoirs with 5 Stage Air/Oil Separation, Including Coalescing Filter.

- (2) Seal Fluid Isolation Valves

- (2) Y-Strainers

- (2) Seal Fluid Line Check Valves

- (2) Separator Drain Valves

- (2) Separator Sight Level Gauges

- (2) Temperature RTD for Discharge Temperature Indication and High Temperature Protection.

- (2) High/Low Oil Level Switches

- (2) Air-Cooled, Heat Exchanger Packages with Main Motor Driven Fan and Fan Guard.

- (2) Inlet Check Valves

- Inlet Manifold Including:

- (2) Inlet Isolation Valves

- (2) Inlet Flex Connectors

- Manifold Piping

- Discharge Manifold Including:

- (2) Individual Pump Drip Legs

- (2) Discharge Check Valves

- (2) Discharge Flex Connectors

- Manifold Piping

- (2) Sets of Hydraulic Hose Seal Fluid Line.

- (2) Inlet Filters

- (2) Vacuum Relief Valves

- Vacuum Receiver

- (1) Horizontal Grasshopper Tank Vacuum Receiver 120 Gallon

- (1) Receiver Sight Level Gauge

- (1) Receiver Drain Valve

- Electrical:

- (1) Duplex ControlDEK Control Panel

- Monitors, measures, and displays performance

- Identifies maintenance and fault conditions, prevents downtime, and preserves system quality.

- Standard 460V, 3 Phase, 60Hz (NEMA12, CUL Listed

- Custom PLC with 4.3” Color Touchscreen LCD with integral hour meter

- Across-line Magnetic Vacuum Pump Starter with 3 Phase Overload Protection

- RTD for discharge temperature indication and high temperature protection

- Vacuum On/Off capability with adjustable set points

- Vacuum transducer, for vacuum level indication

- Pressure transducer, for back pressure indication

- 24V Power Supply

- (1) Duplex ControlDEK Control Panel

- Solberg HV Series Filter UL850/1-200C (Shipped Loose for Field Installation)

- AES-Dekker Laboratory Vacuum System Model AES-VMX0083MA2-00-DS