More Projects

Sutter Roseville “Cart Wash and Ultra Sonic Cleaner” CSPD

December 16, 2021

UC Berkeley Bakar Bioenginuity HUB Laboratory Vacuum System

October 19, 2021

Stanford D&T Mechanical Room Control Air Compressor System Upgrade

September 8, 2021

UCSF 23A Dekker Medical-Laboratory Vacuum System

January 27, 2021

Stanford Valley Care Medical Air Dryer Upgrade Project

December 1, 2020

Sutter Roseville “Cart Wash and Ultra Sonic Cleaner” CSPD

Industry: Hospitals and Healthcare

Type: Equipment

Description

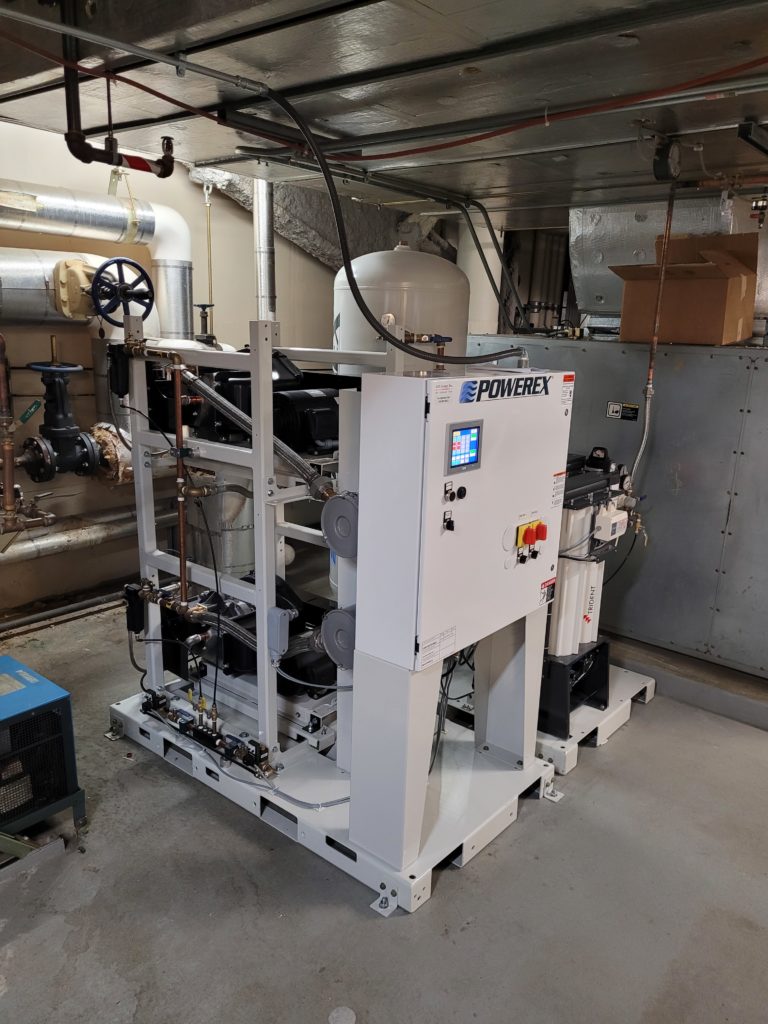

The Laboratory Scroll System is a skid mounted design consisting of multiple oil-less scroll compressors; dual air dryers with purge control, dual filtration system, dew point monitor, wired control panel, and corrosion resistant air receiver. The Laboratory Scroll System shall be modular in design. The Laboratory Scroll System shall be provided with single point connections for electric, discharge air, and condensate drains.

Scope of Work

OIL-LESS SCROLL COMPRESSOR PUMP

The compressors shall be belt driven oil-less rotary scroll single stage, air-cooled oil-less construction with absolutely no oil needed for operation. The rotary design shall not require any inlet or exhaust valves and shall be rated for 100% continuous duty. Direct drive compressors shall not be used. Tip seals shall be of a composite PTFE material and be rated for 8,000 hours operation. Compressor bearings shall be external to the air compression chamber and shall all be serviceable for extended compressor life. Bearing maintenance shall not be required until 8,000 run hours. Compressors with bearings that are not accessible for service have a limited life span and shall not be accepted. Compressors shall have an integral radial flow fan for cooling and shall not require any additional electric cooling fans. Each compressor to be equipped with the following components:

- Isolation, check, and safety valve (1 for each base mount unit)

- ODP electric motor, belts & belt-guard (1 for each base mount unit)

- Air-cooled aftercooler with separator (1 for each base mount unit unless a 10 HP unit, which has one separator for two pumps)

- T.M.P.D. (Thermal malfunction protection device) (1 for each base mount unit)

- Pumps can have all major maintenance performed by only removing the fixed scroll side

- Compressor shall be rated for a minimum 24,000-hour run life

MAINTENANCE-FRIENDLY MOTOR/PUMP BASE-MOUNTS

Patent-pending base-mount service slide provides safe, easy access to common maintenance items. Also includes an adjustable slide base under each motor for ease of belt replacement and tensioning.

RECEIVER TANK

The ASME National Board registered 200 psig working pressure, vertical air receiver is provided with:

- Pressure gauge

- Relief valve

- Sight gauge

- Manual and automatic electric timed tank drain

- 3-valve bypass plumbing

- External paint and internal lining to resist corrosion

PREMIUM NFPA CONTROL PANEL

The control system provides automatic lead/lag activation based on demand and automatic alternation of all pumps to equalize the amount of usage among the available pumps. The control panel shall include:

- A color touch screen panel which displays the operating status of the unit. The touch screen will display pump status, pump faults, pump run hours, system pressure, system alarms and service alert notifications for the pumps, dryers, dew point and CO monitors.

- Building automation communication gateway, through a gateway server card with BacNet® protocol and Web server features. Web server features include email notifications in case the system is in alarm or has achieved one of its maintenance intervals and requires service.

- Ethernet port for connection to BacNet® server or direct connection to facility Ethernet for viewing of system operations and status via device IP-address.

- A PLC controller that includes logic programmed to appropriately manage start-stop, lead-lag and other pump operations.

- UL508A listed control panel in a NEMA 12 enclosure.

AIR PURIFICATION SYSTEM

- Dual heat-less, desiccant air dryers

- Dual pre- and after filters

- Dual pressure reducing valves

- Automatic dew point dependent switching to reduce purge frequency

MONITORING EQUIPMENT

- Dew point monitor with audible/visual alarms & dry contacts for remote alarm signal

SYSTEM CONNECTIONS

The system is supplied with a remote air intake connection and flexible connectors for both intake and discharge. All piping complies with current NFPA 99 requirements. Isolation pads included.

Description

The Laboratory Scroll System is a skid mounted design consisting of multiple oil-less scroll compressors; dual air dryers with purge control, dual filtration system, dew point monitor, wired control panel, and corrosion resistant air receiver. The Laboratory Scroll System shall be modular in design. The Laboratory Scroll System shall be provided with single point connections for electric, discharge air, and condensate drains.

Scope of Work

OIL-LESS SCROLL COMPRESSOR PUMP

The compressors shall be belt driven oil-less rotary scroll single stage, air-cooled oil-less construction with absolutely no oil needed for operation. The rotary design shall not require any inlet or exhaust valves and shall be rated for 100% continuous duty. Direct drive compressors shall not be used. Tip seals shall be of a composite PTFE material and be rated for 8,000 hours operation. Compressor bearings shall be external to the air compression chamber and shall all be serviceable for extended compressor life. Bearing maintenance shall not be required until 8,000 run hours. Compressors with bearings that are not accessible for service have a limited life span and shall not be accepted. Compressors shall have an integral radial flow fan for cooling and shall not require any additional electric cooling fans. Each compressor to be equipped with the following components:

- Isolation, check, and safety valve (1 for each base mount unit)

- ODP electric motor, belts & belt-guard (1 for each base mount unit)

- Air-cooled aftercooler with separator (1 for each base mount unit unless a 10 HP unit, which has one separator for two pumps)

- T.M.P.D. (Thermal malfunction protection device) (1 for each base mount unit)

- Pumps can have all major maintenance performed by only removing the fixed scroll side

- Compressor shall be rated for a minimum 24,000-hour run life

MAINTENANCE-FRIENDLY MOTOR/PUMP BASE-MOUNTS

Patent-pending base-mount service slide provides safe, easy access to common maintenance items. Also includes an adjustable slide base under each motor for ease of belt replacement and tensioning.

RECEIVER TANK

The ASME National Board registered 200 psig working pressure, vertical air receiver is provided with:

- Pressure gauge

- Relief valve

- Sight gauge

- Manual and automatic electric timed tank drain

- 3-valve bypass plumbing

- External paint and internal lining to resist corrosion

PREMIUM NFPA CONTROL PANEL

The control system provides automatic lead/lag activation based on demand and automatic alternation of all pumps to equalize the amount of usage among the available pumps. The control panel shall include:

- A color touch screen panel which displays the operating status of the unit. The touch screen will display pump status, pump faults, pump run hours, system pressure, system alarms and service alert notifications for the pumps, dryers, dew point and CO monitors.

- Building automation communication gateway, through a gateway server card with BacNet® protocol and Web server features. Web server features include email notifications in case the system is in alarm or has achieved one of its maintenance intervals and requires service.

- Ethernet port for connection to BacNet® server or direct connection to facility Ethernet for viewing of system operations and status via device IP-address.

- A PLC controller that includes logic programmed to appropriately manage start-stop, lead-lag and other pump operations.

- UL508A listed control panel in a NEMA 12 enclosure.

AIR PURIFICATION SYSTEM

- Dual heat-less, desiccant air dryers

- Dual pre- and after filters

- Dual pressure reducing valves

- Automatic dew point dependent switching to reduce purge frequency

MONITORING EQUIPMENT

- Dew point monitor with audible/visual alarms & dry contacts for remote alarm signal

SYSTEM CONNECTIONS

The system is supplied with a remote air intake connection and flexible connectors for both intake and discharge. All piping complies with current NFPA 99 requirements. Isolation pads included.